Home : Chairlifts :

Facts & Features : Eskimo

Lift Destruction

Eskimo

Lift Destruction

Performed

on June 18-19 in 1990 at the Winter Park Ski Resort in Colorado,

W.P.R.A & Jenlynn Inc. performed several test on a 1963 Riblet

center pole fixed grip double chair to see what would happen if

any of the tests performed would happen in a real life scenario.

For more information about the Eskimo lift destruction test, you

can order the SAM Magazine issue of September of 1990 (SAMinfo.com)

and/or check out the Eskimo lift destruction video which is available

on NSAA website (NSAA.org) for $500. If $500 is too much for you,

there are some libraries in the United States and maybe Canada that

actually have this video which you can check out by going to your

local library and ordering it that way.

Lift Statistics:

- Manufacturer: Riblet

- Installed: 1963

- Type: Center pole fixed grip double chair

- Slope Length: 4,320 feet

- Vertical Rise: 1,212 feet

- Speed: 500 FPM

- Capacity: 1000 PPH

- Chair Spacing: 160 FT

- Number of Chairs: 155

- Line Guage: 1,0' 1"

|

- Drive Equipment:

- Power: 150 HP/ Vault Drive

- Brakes:

- Cable Backstop: TRB

- E-Brake: Yan 1500 Cal.

- Service Brake: Spring APPL. and Hydraulic Release.

|

Tests Performed:

- Brakes

- Rollback

- Oily Rope

- Tree on Line

- Fire

- Tower Pull

Day One:

The first set of tests that were performed were those concerning

the lift's braking system. The service, emergency and traction rope

brakes had already been torqued tested to the standard prescribed

values before the test was started. The chairlift was loaded with

concrete discs that weigh 57 pounds each and were placed equally

on 72 of the 155 chairs to bring the total weight of 29,000 pounds.

The weight represented 110 percent of the lift's full uphill design

load. When the first brake test started, both the service and emergency

brakes were applied individually with the lift traveling in a reverse

direction with a line speed that reached a maximum speed of 550

feet per minute (FPM), 50 feet faster than its designed speed.

When the lift was operating in reverse at a speed of 400 FPM, it

failed to stop when the service brake was applied which became inoperable

due to the heat that was being generated in the brake shoes. However,

in order to stop the the lift, the bullwheel brake had to be applied.

The bullwheel brake was a Yan 1500 acting directly on the flange

of the bullwheel.

The test was performed again with the lift reaching a maximum reverse

speed of 550 FPM and only the bullwheel brake being applied to stop

the lift. The lift stopped adequately with a maximum deceleration

of 1.52 ft./s2, although at the haul rope derailed at the top station

when a chair got lodged into the guidage.

For the last test that was performed in this series, the main drive

shaft that was connecting the gear reducer to the bullwheel was

disconnected at the coupling adjacent to the gear reducer. The lift

was allowed to travel in reverse with a couple of loaded chairs

passing around the bullwheel. It was then instructed that the chairlift

be stopped using the bullwheel brake, but since this lift has two

stop buttons, the normal stop button was depressed inadvertently

instead of the one for the bullwheel brake. Because of this, the

lift gained a tremendous amount of speed in the reverse direction,

reaching speeds up to 1500 FPM. The 57 pound concrete disk that

were placed on the chairs were thrown 120 feet into the air from

the center of the bullwheel. Chairs were dislodged from the haul

rope and flung in different directions causing them to become tubular

steel pretzels after going around the bullwheels. During this rollback,

the chairlift traveled 1440 feet or 24 chair lengths resulting in

total destruction of the carriers that went around the top and bottom

bullwheels. The guidage rails for the top and bottom stations were

damaged beyond repair and one carrier managed to get lodged into

the lower stations guidage rails. The track rope brake was quickly

applied, but because of the speed the lift was traveling and the

chairs that were attached to the haul rope, the chairs moved the

haul rope out of the track brake. The chairlift eventually slowed

down and came to a stop because of the forces of destruction.

Day Two:

After a tremendous amount of work from the Winter Park crew to get

the lift operational again after destructive rollback, testing resumed

on schedule on June 19th. There were no chairs on the haul rope

from 51 to 72 since they all had been piled to scrap from the severe

rollback. Also, there were no sheave assemblies on the upgoing side

on towers #18 and #20 because they were damaged during the same

test too.

The third test that was performed was the oily rope test, to simulate

what would happen if there was an oil leak with oil getting on the

haul rope and bullwheel. To perform this test, crews lathered the

haul rope and bullwheel oil and used the bullwheel brake to try

and stop the lift. While the lift was being driven uphill, the haul

rope would slip relative to the drive linear/sheave generating a

considerable amount of heat, reaching around 250 degrees fahrenheit

(The bullwheel brake wasn't applied in this test and heat was generated

from the bullwheel still in motion while the haul rope wasn't in

motion). The process was repeated again, but this time the lift

was running in reverse at a line speed of 750 per minute. When the

bullwheel brake was applied, the haul rope continued to slip on

the bullwheel linear/sheave.

The fourth test that was performed was to see what would happen

to a lift if a tree fell on the haul rope if it was in motion. With

the lift operating uphill again, a tree 35 feet from tower #4 was

cut and allowed to fall on the downgoing side of the haul rope.

There was no carriage movement upper terminal, at tower #4A the

haul rope was off the sheaves, while the cable catches on towers

#2, #3, #4 suporrted the downgoing haul rope. This test was performed

again at towers #16 #19, but the effects wern't as major as the

first tree on line test. However, unlike the first test, in both

the second and third test, the haul rope didn't derail from the

haul rope when a tree fell on the upgoing line.

The fifth test that was performed was the most dramatic of them

all. The fire test was carefully planned, including the fire department

ready incase another fire broke out that wasn't planned. Trees and

nearby foilage were soaked prior to the start of the burn.

The Eskimo's motor room was located in a concrete vault below the

lower bullwheel and had a structural wood roof covered with asphalt-based

materials. The only piece of equipment that was removed from the

motor room prior to the fire was the auxiliary power unit. The fire

was started by using some oily rags and placing them near a work

bench. About 27 seconds after the fire was set, it was evident to

the people around the lower station. About a minute and thirty five

seconds after the fire was started, the lift came to a stop from

the bullwheel brake hydraulic pressure line being severed by the

fire. After 14 minutes after the fire became evident, the haul rope

finally seperated causing the chairs to drop to the ground. The

temperature at the bottom station from the fire reached as high

as 1,800 degrees F only 6 minutes after the fire was evident. The

fire was eventually put out by the fire fighters after 21 minutes

into the burn.

The final test that was performed was to test out the lateral loads

on towers to attempt to pull them out of the ground. Even though

this was the least exciting test of the 6 tests that were performed,

there was a lot of knowledge gained from this test. There was a

total of four tower foundations that were tested during this test,

two deep footed foundations by Riblet and two shallow tower foundations

by Lift Engineering/ Yan. During this test, there were forces that

were applied to both the top and bottom of the towers. Both the

Riblet tower foundation footings failed having structural tubing

issues, one by failure of the collar weld while the other failed

do to the tower tube bending. Both of the Lift Engineering towers

also failed because of uprooting from the ground.

Tower "Constructive Destruction" Table

| TOWER NUMBER |

FAILURE LOAD # |

LOAD ANGLE |

TOWER ANGLE |

HEIGHT FT. |

BASE MOMENT K-FT |

| *5A |

6,875 |

21.8 |

2.6 |

35.2 |

228.5 |

| 5 |

14,300 |

19.4 |

13.1 |

31.3 |

447.5 |

| *4A |

12,106 |

14.4 |

5 |

26.75 |

323.6 |

| 4 |

19,250 |

11.7 |

3 |

30 |

570.8 |

| 4 @ YIELD |

9,240 |

13.3 |

2.4 |

30 |

272.2 |

*A Towers indicate shallow block footing design.

All pictures belong to Jenlynn Inc. Content gathered

from SAM Magazine ©

| |

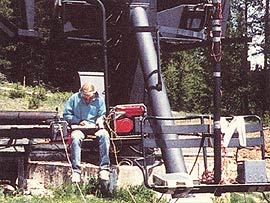

Tad

Nordstrom of Jenlynn sits behind a chair with computer measuring

equipment. |

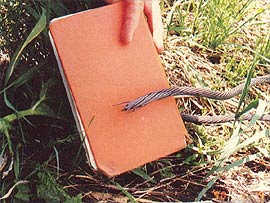

| |

Rosette

strain gauges were placed on some of the chairs hanger arms

to measure the activity at various locations on the lift, along

with chairs passing around the bullwheels. |

| |

A

Riblet carrier still hangs from the haul rope after its hanger

arm was severely bent after it passed around the bullwheel during

the rollback test.

Workers of Winter Park and Jenlynn survey the damage of the

Eskimo lift after the rollback test was performed. |

| |

A

Riblet carrier is seen here lodged upside down into tower 2

causing the haul rope to derail off of the sheave assembly. |

| |

Another

carrier is lodged into the lower station's guidage rails causing

damage to them. |

| |

Here's

a shot looking up the lift line after several carriers were

destroyed after they passed around the lower bullwheel during

the rollback test. |

| |

The

hanger arm of chair #74 is snapped in half after it was broken

during the rollback, but the safety rode (wire) kept the chair

intacked after the test. |

| |

A

sheave axle lays on the ground after it failed catastrophically

during the rollback test. |

| |

A

chair's clip is still attached to a severed section of the haul

rope after the carrier got caught on an object, but eventually

the chair broke free from the clip. |

| |

The

tree on line test was performed just above tower #4 on the down

going rope side. This test was performed 3 times while the lift

was running. 2 times near the top station, while 1 time near

the bottom station. The tree that fell near the bottom station

did the most damage to the lift do to its size and weight. |

| |

One

of the last and most dramatic test that was performed was the

fire test. The test was designed to see what would happen if

a fire were to break out in a lift's motor room. The picture

on the left was taken about 14 minutes after the fire was started

and the entire station is engulfed in flames. The lift's haul

rope snapped right before this picture was taken. |

| |

The

strand of wire on the left is the result of the fire which resulted

in the ductile failure of the individual wires. |

| |

Fire

crews were ready incase the staged fire got out of hand. |

| |

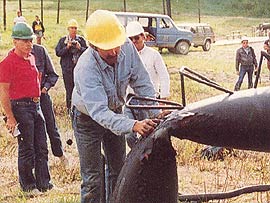

The

last and final test that was performed on the Eskimo lift was

the tower pull. There were four tower foundations tested, consisting

of shallow and deep tower foundations. The tower on the left

is of tower 5A with a shallow block tower footing design and

it was easily pulled over with the foundation coming out of

the ground. |

| |

This

is the result of tower 5 with a deep block footing. Even though

it showed little movement during the pull, it failed because

of bending. |

All pictures belong to Jenlynn Inc. Contenet gathered

from SAM Magazine ©

|